BESA Accredited Training & Competency Assessment

Fantastic news yesterday, after months of hard work & refurbishment we have finally been approved as one of the First training centers to be able to offer the BESA Short courses for Ventilation hygiene.

We have a fully fitted training school based in Ossett West Yorkshire & Soon to be opened in Partnership with Swiftclean in Southend Essex.

Keep an eye out on our website for the first Grease Hygiene Operative course, we are taking bookings as we speak, contact info@iaqservices.co.uk for more details.

This course is aimed at those who are working in or have just started working within the building engineering services grease extract hygiene industry, with more courses to follow shortly for Technician level employees in both Grease and Air disciplines.

The course is the only nationally recognised, third party accredited training course and consists of both theory and practical activities, which delegates will be assessed across both.

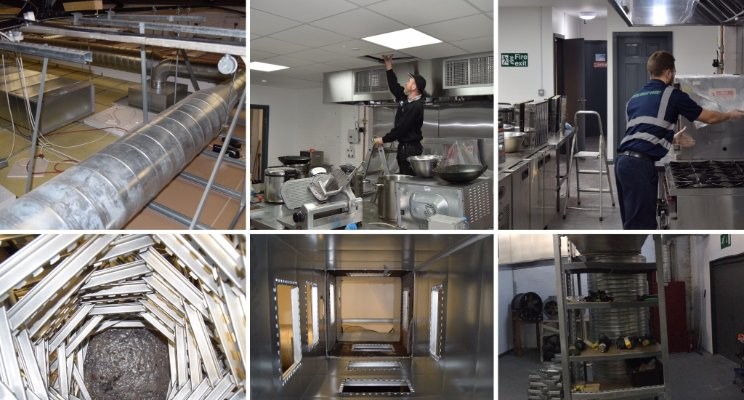

The theory and practical exercises include:

• Safe working practices

• The principles of kitchen grease extract systems and associated components

• Preparing the work location

• Cleaning of kitchen grease extract systems and associated components

• Working sustainably

• Problem solving

The delegates will be trained and assessed on all of the above. They will be expected to prepare the work location, insert access panels and clean kitchen grease extract systems and associated components. They must select the correct materials, tools & equipment to carry out the activities and they must apply the correct cleaning methods and techniques to meet TR/19 and industry standards.

ON COMPLETION OF THE COURSE DELEGATES WILL:

• have an understanding of health, safety & environmental issues with the workplace

• appreciate the importance of sustainable working

• have an understanding of the principles of kitchen grease extract systems and

associated components

• know how to prepare the work location for cleaning activities to be carried out

• be able to select the correct materials, tools and equipment for the work activity

• have the ability to insert suitable access panels

• have the ability to safely carry out the correct cleaning methods and techniques

• be able to problem solve within their scope of responsibility

• appreciate the importance of leaving the work area clean and tidy

Poor standards or poor design?

All too often duct cleaning contractors are accused of poor standards, especially here on LinkedIn. Let’s explore this a little further.

I’ll hold my hands up, I’m guilty of this myself, but is it fair to blame the ductwork cleaning contractors all the time?

As many of you may know I am an Independent Consultant, my company specialises in, among other things, auditing and inspecting grease extract systems.

Of the 1000 or so audits we carry out each year at least 50% will fail for various reasons, but I would hazard a guess that only 10% of that half can be contributed to poor contractor standards, be it poor cleaning or poor reporting practices.

The other 40%? Usually system design, second fix services and just the wrong building for the intended use.

I consider grease extract ductwork as an essential service and as such access to these critical systems should be considered as a priority during the planning, design and construction phase. How many other building services require regular access? sometimes on a monthly basis.

Did you know that EC852, part of the food safety legislation states that ductwork must be accessible for maintenance and cleaning. Does this mean that it is illegal to have, design and install ductwork that cannot be accessed for cleaning? I’ll leave you to discuss this later.

All too often the best designed system has its access doors blocked by supply ductwork, cable trays, A/C pipework etc etc.

How many times have you heard ” the reason the duct is there is because there is no where else to put it” Sorry in my eyes that just means that the building isn’t suitable for use as a restaurant.

Why is this still happening? I cringe at some of the posts on LinkedIn, from proud ductwork installers showing off their latest shiniest project, i have to bite my tongue and try hard not to spout DW172, EC852, TR19 etc etc.

I also am not naive enough to know it’s always the installers fault, more often than not they are working to a set of design drawings, does this mean there should be a more robust route for these designs to me challenged with the main contractor?

Quite often large tenders are run at prices that just are not sustainable, the first thing to happen in this instance is standards drop, with the end user being left in the position of either not being insured or not fulfilling their obligations under the RRFSO 2005. if the system isn’t cleaned fully, it isn’t worth cleaning at all as the risk from fire still remains. Gone are the days when the industry promoted “fire breaks” and “cleaning to arms length” how very 1990’s

Getting customers to spend £1000’s on making ductwork accessible can be a difficult sell, and i feel sorry for them sometimes. If you where a new restaurant and you employ somebody to design and build your lovely new Vegan wrap restaurant then you would expect that it is built and delivered fit for purpose and not have to rip out half the kitchen after 6 months of trading.

I’ll stop here as i could go on for ages, what i am trying to say is that dont be so quick to blame the obvious choice!